When 3D printing first came along, many people thought it was the end of injection moulding. Why bother to set up expensive tooling for moulds when you could load up a CAD program, see the object and press print? Needless to say, it hasn’t quite turned out like that. 3D printing and injection moulding are now often used together, even though each has a quite different process for achieving its ends.

Print for Prototyping, Then Moulding for Manufacturing

There’s now a widespread process by which 3D printing is used to produce the prototype of a plastic component or to produce the injection mould tools.

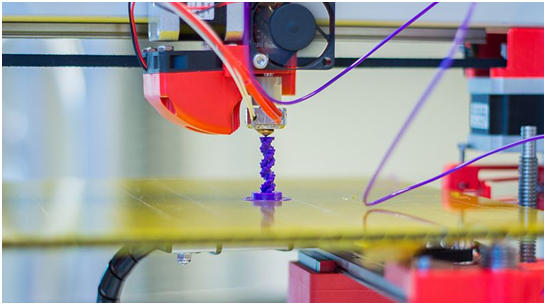

A 3D-printed object is made by taking minute slices through the object and building them up in layers to make the finished object. There’s no limit to the complexity of a slice of a 3D-printed object – a slice representing a vehicle can include the wheels, which in the finished object will be able to move and turn.

3D printing still tends to be a tool for one-offs, tools, components and prototypes. But as the printers develop, they are coming into their own in producing custom medical aids and in veterinary applications.

And 3D printing is also a great tool for engineers who are producing components that will be used in a manufacturing process – it gives them results much more quickly.

3D Struggles with Volume

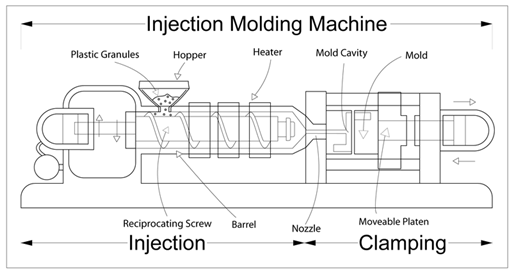

However, until recently, 3D printing hasn’t been seen as a practical option for manufacturing because it has been unable to cope with the volume required at the cost levels that would make it economic. For that, businesses head to a plastic injection moulding company such as http://pnplastics.co.uk/, which can produce even complicated items in volume and more cheaply. Complex shapes can be produced in great numbers at very high speeds.

The tools that produce these items can be reused over many years, producing very large economies of scale as millions of items may be produced. Of course, the initial design and tooling up is expensive. However, the items produced by injection moulding come out as finished products. Those that have been 3D-printed often require further finishing after the main process is complete.

In the next few years, we’re likely to see more examples of both technologies working together.